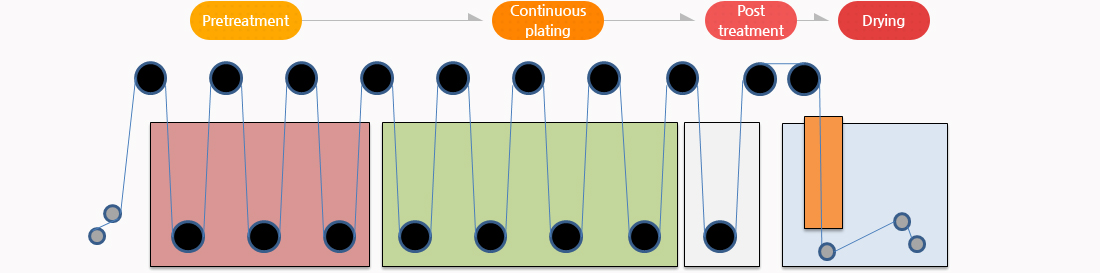

SPL (Special Plating Line) Information

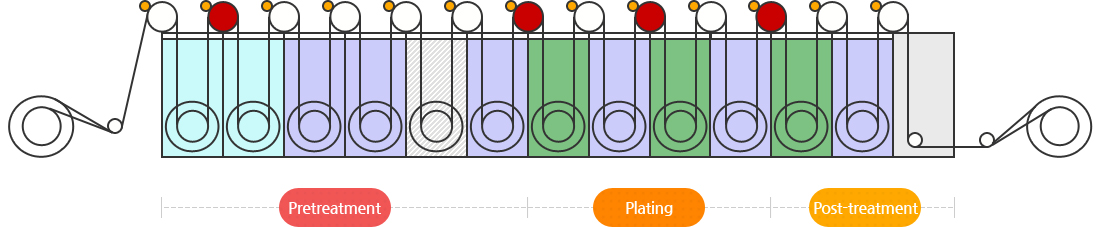

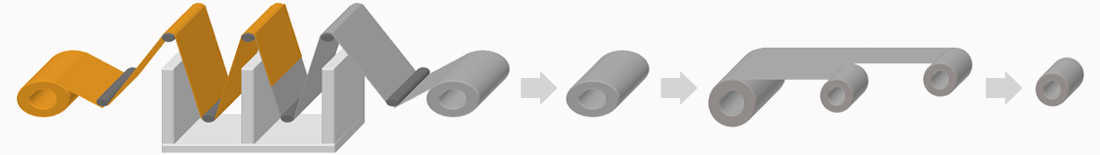

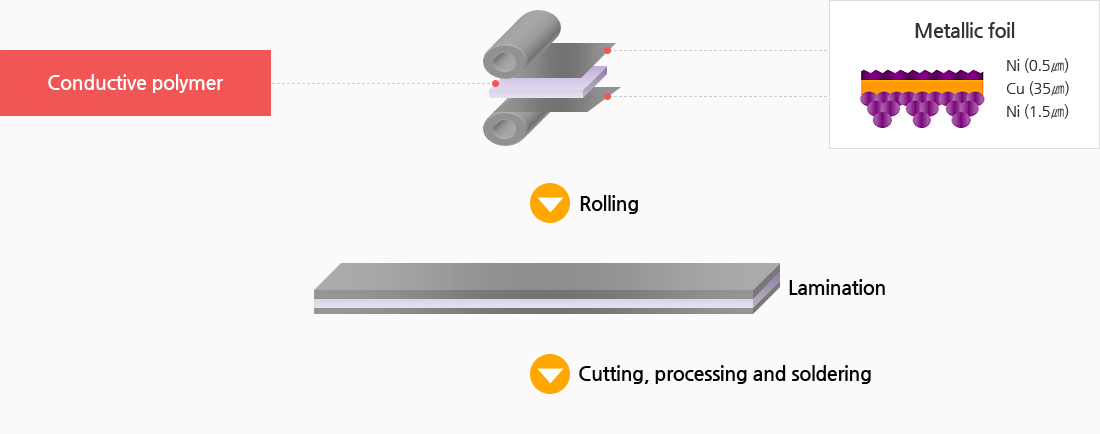

| Plating Line | Roll to roll continuous plating line | Material Thickness | Facility capable of ultra thin foil plating under 20 µm |

|---|---|---|---|

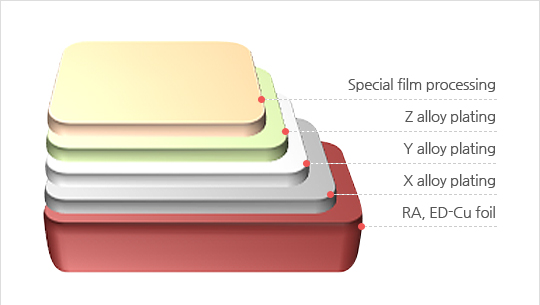

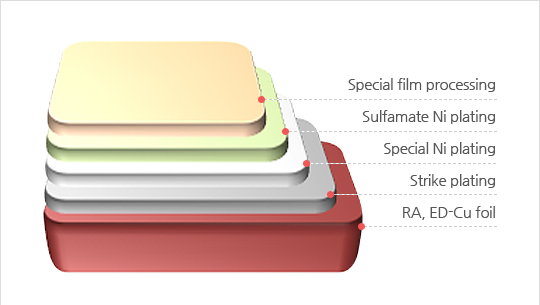

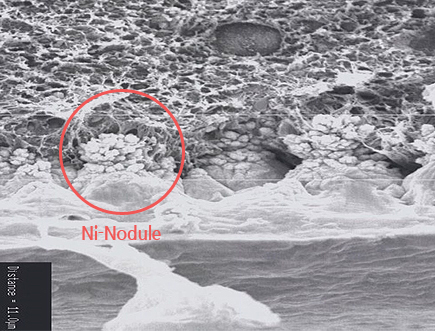

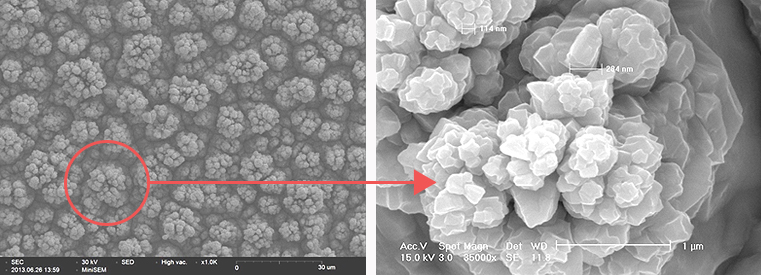

| Plating Types | Corrosion resistant plating, Ni plating | Width | 550mm max. |

| Purposes | Electromagnetic field covering and heat resistant sheet | Line speed | 10 ~ 20mpm |

| Monthly Average Production Capacity (Corrosion Resistant Plating) | 350,000m(15m/min) | Monthly Average Production Capacity (Ni Plating) |

250,000m(10m/min) |