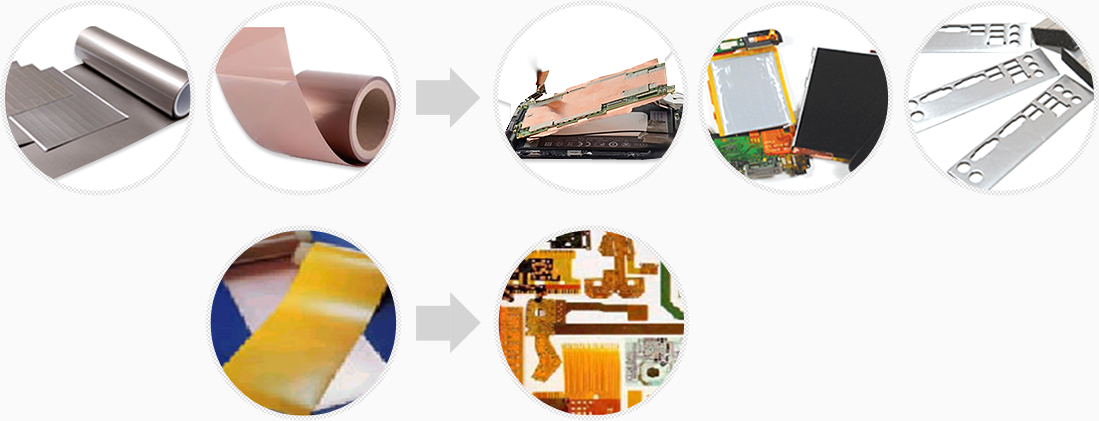

Overview of Technological Development of Black Plating

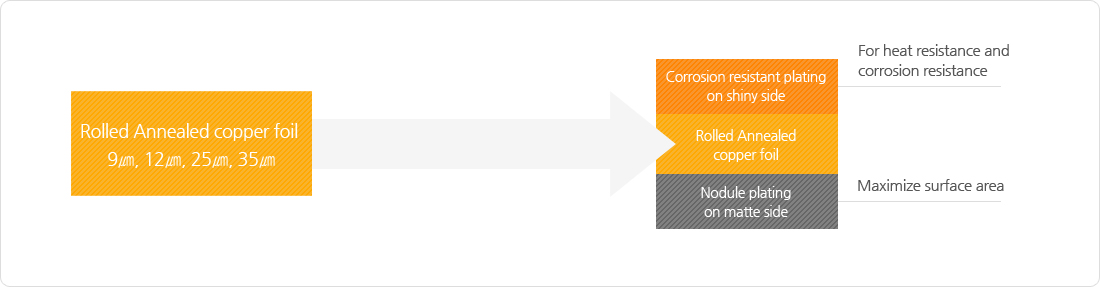

- Developed nodule plating technology and corrosion resistant plating technology using rolled copper foil

- Nodule is formed on the matte side, maximizing the surface area for higher adhesion strength whereas the shiny side is plated for heat resistance and corrosion resistance

Characteristics of Olated Foil

- Maximized adhesion strength through hundreds of

nano sized micro nodules

- Superior heat resistance property through increasing surface area

- Corrosion resistance and heat resistance of product through post-process plating

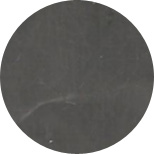

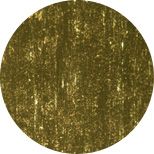

Surface Color

| Jeonyoung | Company A | Company B | |

|---|---|---|---|

| S-side | Yellow | Pale yellow | Redish |

| Color |  |

|

|

| M-side |  |

|

|

| Color | Dark-black | Red-black | Dark-black |

Microscopic Images

| Jeonyoung | Company A | Company B | |

|---|---|---|---|

| S-side (x30) |

|

|

|

| M-side (x200) |

|

|

|

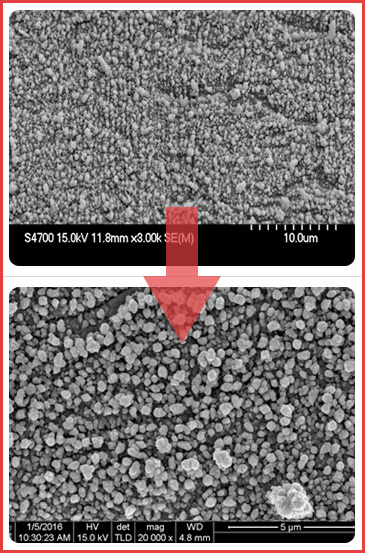

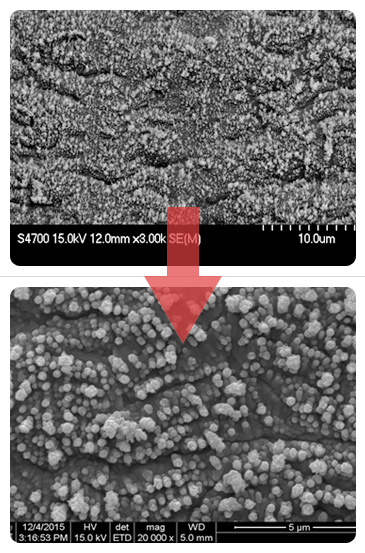

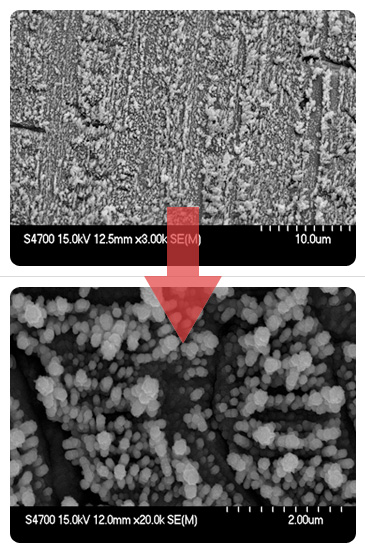

SEM Image of M-Side

| Jeonyoung | Company A | Company B |

|---|---|---|

|

|

|

Our nodules are more densely formed for increased adhesion strength. (Number of nodules/ μ㎡: Jeonyoung > Company A > Company B)

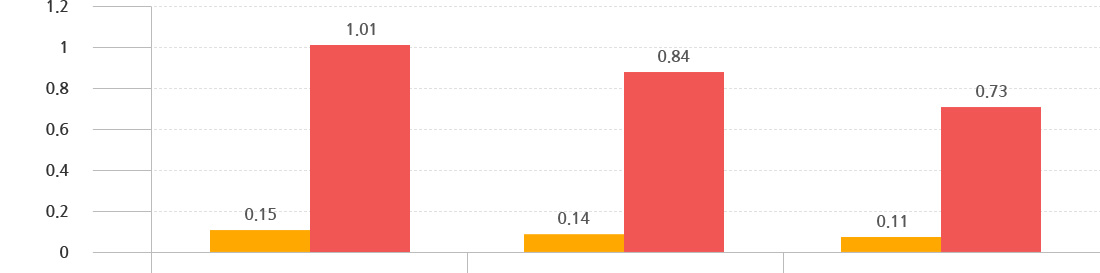

Roughness

- Ra

- Rz

| Jeonyoung | Company A사 | Company B사 | |

|---|---|---|---|

| Rz | 1.01 | 0.84 | 0.73 |

| Material thickness | 35㎛(25㎛) | 35㎛ | 35㎛ |

| S-side Ra | 0.14 | 0.11 | 0.11 |

| Rz | 0.95 | 0.62 | 0.68 |

| M-side Ra | 0.15 | 0.14 | 0.11 |

We have maximized Rz to increase adhesion strength.

Thermochromic Test Result (30 minutes at 200℃)

| Jeonyoung | Company A | Company B | |

|---|---|---|---|

| Before |  |

|

|

| After |  |

|

|

| Result | OK | OK | OK |